200 KW Solid State Welder

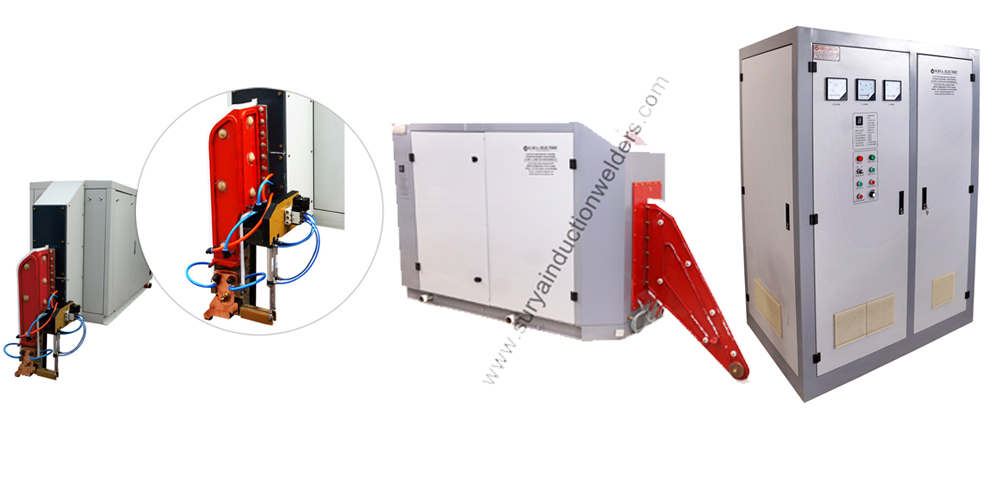

Center control console

Center control console

Inverter cabinet

Inverter cabinet

Detailed Description

Brief Introduction

200 KW Solid State Welders are used in the process of manufacturing welded steel tube, pipe and structural square and rectangle tubing. The welders are installed inline on a tube mill and are used to weld the seam of the open edge of the tube after it has been formed from a flat strip by the tube mill. This welding is done continuously at up to hundreds of feet per minute. The weld is produced by the welder using high frequency sound waves (heat). These high frequency sound waves are concentrated on the open edges of the formed tube until the edges of the formed tube are red hot. The edges are forced together by a series of rolls to form the weld seam.

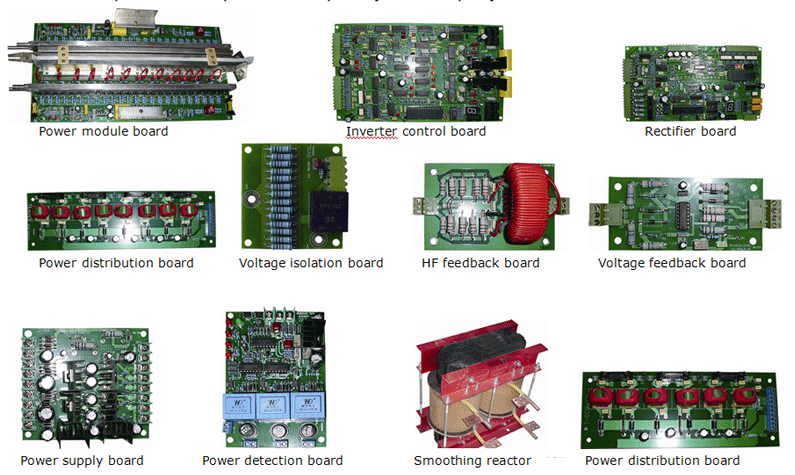

The basic principal of solid state high frequency is that 3-phase AC current voltage is reduced by the step down transformer, and then enter into the rectifying cabinet through the rectifying, regulating voltage and filtering and become continuously adjustable DC; then enter into the inverter bridge(using high-power transistor MOSFET) and become high frequency current, and this high frequency is suppliedto the load tank circuit and then can be used for the induction heating. Inverter tank circuit power unit using the modular structure, and each power unit can output above 200 KW, the number of the power unit is different according to different power equipment. The tank circuit is a kind of series and parallel mixing form, no high voltage and no output transformer.

Equipment Advantages

1.No high voltage, safety, reliability and high efficiency.

2.The main components are using foreign brands products, such as: IR, IXYS and Siemens.

3.Voltage and Current Double-fed control circuit, stable adjustment, high precision and little interference.

4.Power range 0-100% step-less adjustable, have the advantages of over-voltage, over-current etc. fault protection system.

5.Digital display, simple operating, convenient maintenance.

6.High quality welding, uniform welding seam width, uniform temperature, less burrs in welded tube surface and inner.

Operating Environment

This equipment is designed for indoor installation, should avoid the rain, frost and snow, sun exposure, it should also meet the following conditions:

1.No more than 1000 meters altitude, too high altitude will reduce the air pressure result in bad cooling effect.

2. Ambient temperature -5 ℃ --- + 40 ℃, (less than 0 ℃ should prevent freeze, result in the cooling pipe blocked and damaged).

3. Relative air humidity less than 85%.

4. No conductive dust explosion, no gas and steam can rust the metal and damage the insulation.

5. No severe vibration and shock

If does not meet the above-mentioned requirements, the customer should notified our company and we can consider carefully in the equipment design.

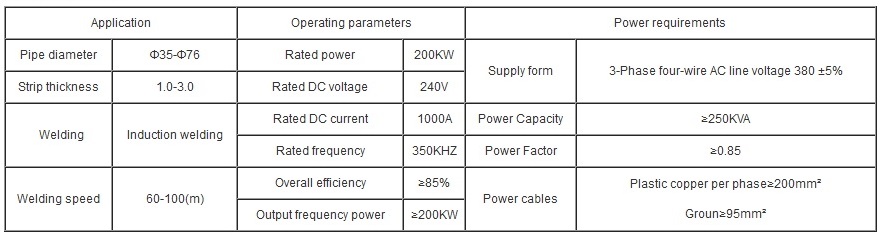

Specifications

Power saving &efficiency

Stable and continous working

Full digital control system

HMI and fault diagnosis system

50 KW to 800 KW Pipe solid state HF welder

The whole set of solid state H.F. welder comprises of switchgear rectifying cabinet, inverter output cabinet,

connecting optical fiber, circulation soft water cooling system, central operator console, mechanical adjustment device,

contact welding pole plate and contact pin (contact welding) and etc .